Designtex announced its partnership with West Elm in the design, manufacturing, and production of 13,000 cotton face masks to support COVID-19 pandemic efforts in its state-of-the-art Surface Imaging facility in Portland, Maine.

Protecting the health and safety of essential workers and community members remains a top priority as the COVID-19 pandemic continues to evolve. After a generous donation of 400 thread-count organic cotton sheets from West Elm, Designtex has been able to prototype cotton face masks with materials on hand in their Portland manufacturing facilities.

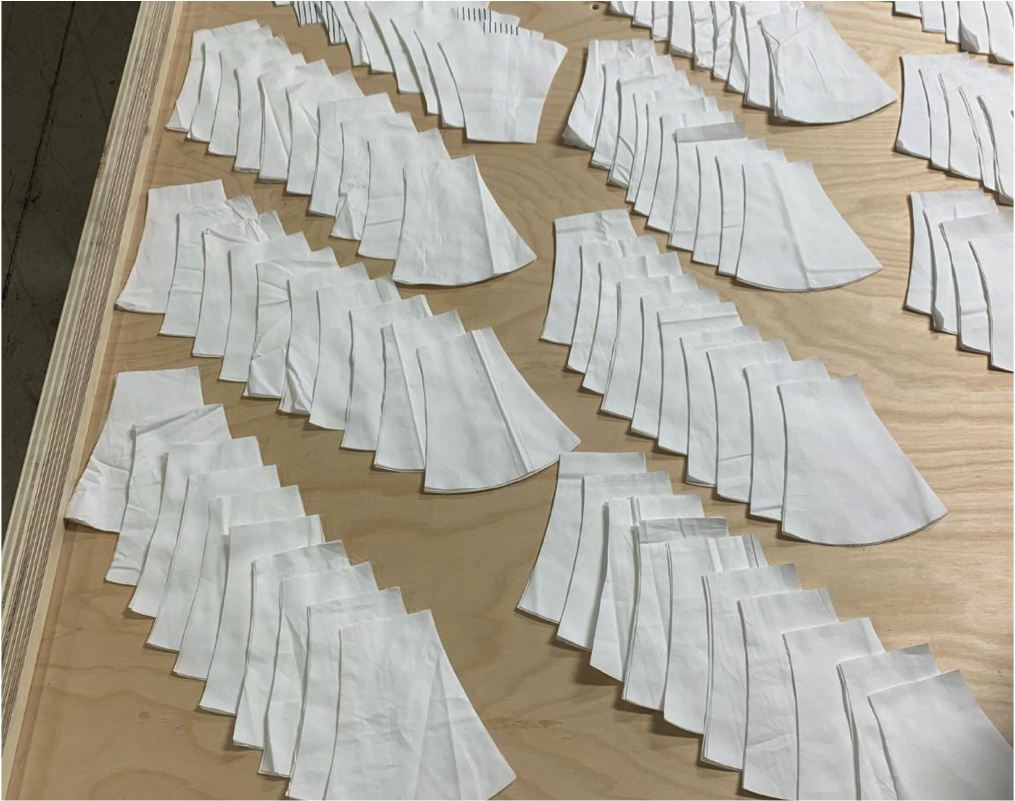

Designtex West Elm face masks are highly launderable and breathable. After unpacking 120 sheet sets from West Elm, the cotton fabric is trimmed for manufacturing. Each mask is made using two layers of 400-thread count organic cotton. With rotary-style cutting on Designtex’s Zund G3 platform, production is quick, cutting close to 60 half-mask pieces in four minutes. Half mask shapes are seamed to become full masks, and a sliding cord allows for fastening and an adjustable fit. When cord procurement presented an obstacle, Designtex slit our own strong and soft microfiber tie for safe and reliable fastening.

From unpacking sheets, uploading patterns and cutting, to sewing and cord threading, Designtex is capable of producing 300 masks per shift for a total of 13,000 cotton masks. The first 500 Designtex West Elm cotton face masks have already left the production line to reach those most in need, and the partnership is confident in their ability to supply the remainder to the non-profits to whom they have pledged support.